Seal the Deal: Discover the Perfect Closures and Caps for Your Products

In addition to the quality range of jars and bottles provided by Pont Packaging, also matching closures and caps are available. These closures and caps are inevitably needed to perfectly close the packaging. They also create an extra layer of protection against contamination and leakage.

Closures and caps are available in different materials, sizes and colours. It is important to consider specific needs of your product and the selected containers when choosing the right closure to ensure the best possible closing, protection and functionality.

Closures for your packaging

Closures and Liners Contents

Pont constantly strives to offer the best sustainable packaging options available focusing on a circular economy. We advise on material and designs that are both sustainable and more effectively recycled.

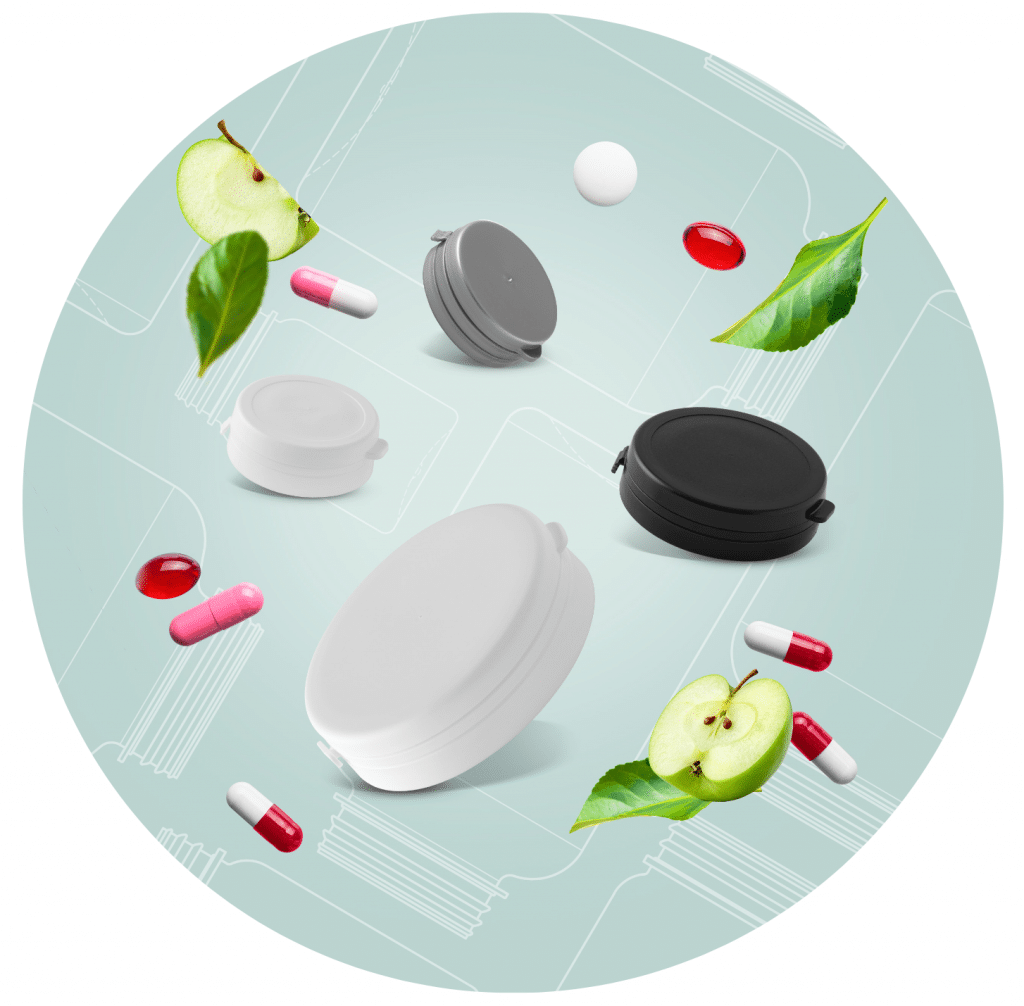

Hingegard caps

Hingegard caps can only be used when the neck finish of the jar is created to contain a hingegard cap. Hingegard caps are also made of polymers. They offer several benefits over traditional screw closures, such as:

Mono-material: when the material of the closure and jar is from the same kind, the combination is perfect for recycling, depending on size and colour

Convenience: caps can be opened with one hand which can be particularly convenient for on-the-go use, such as with travel-sized products or snacks

Tamper-evidence: tear strip to provide safety and integrity to your product

Improved product freshness: a tighter seal to keep products fresher for longer and reduce the risk of spills or leaks

Versatile: possible to either use a liner or a cone for extra product protection

Hingegard caps can provide other benefits for both manufacturers and consumers. From the convenience of use to the sustainability for your brand, these caps offer a versatile and practical packaging solution to a variety of products.

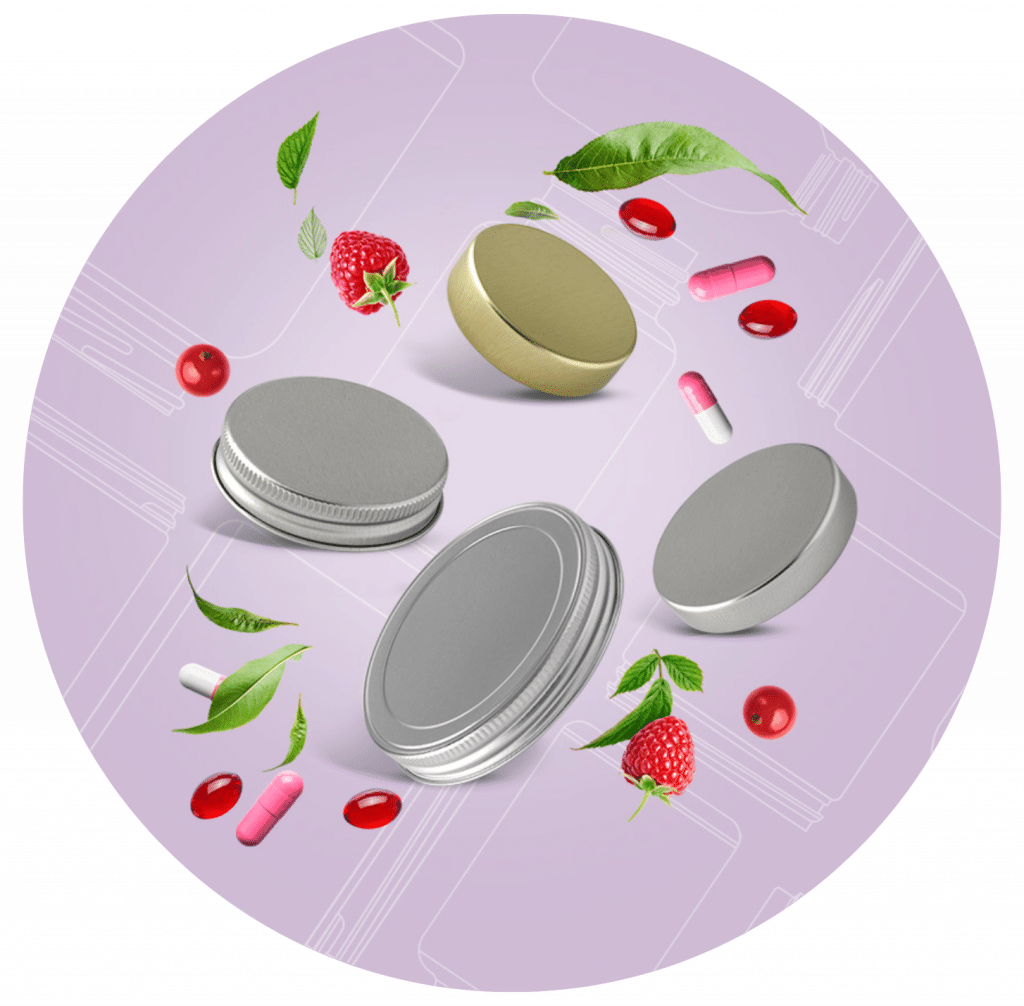

Metal or aluminum closures

While polymer closures have many benefits, there are also some reasons why a metal or aluminum closure may be preferred in certain situations. Some of the benefits of metal or aluminum closures are:

- More durable closure for products that require a high level of protection or are exposed to severe environmental factors

- Good oxygen barrier which is important for products sensitive to oxygen such as certain food products

- High-end premium look that may be appreciated by some customer so a nicer aesthetic appeal

- High-temperature resistance which can be important for products that require pasteurization or sterilization

- Recyclable to help reduce waste and minimize the environmental impact

Metal or aluminium closures may be preferred in situations where durability, oxygen barrier, aesthetic appeal or high-temperature resistance are important factors.

Polymer or plastic closures

Polymer closures are a popular choice for many applications due to their affordability, durability and versatility. They are available for various screw neck finishes with denominations such as CT, ROPP, DIN, GPI and are also available as child-resistant version.

- Lightweight material that make them very convenient to handle

- Cost-effective in production and transportation thanks to the low weight

- Resistant to corrosion to protect products exposed to moisture or other unfavourable ecological conditions

- Versatile to fit a wide range of container sizes and shapes, including features such as child-resistance and tamper-evidence

- Recyclable to help reduce waste and minimize the environmental impact. This is dependent on size and colour.

Liners

A liner is a material that is placed inside the closure or cap to provide a seal between the closure and the bottle or jar. The liner is mostly made from materials such as foam or plastic. There are different kind of liners available for the closures provided by Pont Packaging:

What is a liner?

- Pressure sensitive (PS): Pressure-sensitive liners are self-adhesive (on one side), designed to stick on the rim of the container. They provide an extra level of protection but are not considered as tamper evident. PS liners are not suitable for liquids.

- Induction heat seal (IHS): Induction liners use electromagnetic induction to generate heat in the foil layer of the liner, which melts the sealant layer and bond the liner to the container, creating an even stronger seal. They create an airtight seal and tamper evidence.

- EPE foam: Foam liners are made of a compressible material and are often used for products that require a tight seal, such as pharmaceuticals or food. However, the EPE liner is not connected to the container. It is often used for liquids.

- Cone (only for hingegard caps): a cone is an alternative to a liner and can only be used in hingegard caps. It ensures an airtight sealing and has the benefit that no liner is needed which improves the recyclability and thus the sustainability. Thanks to the cone, the cap stays open after opening.

Why to use a liner?

- Prevent leakage: one of the primary functions of a liner is to prevent leakage of the content inside. The liner ensures that it remains tightly sealed.

- Prevent contamination: a liner keeps the product separated from the closure or cap material. This is particularly important for food and pharmaceutical products.

- Ensure freshness: a liner can help to maintain the freshness of a product by preventing air, moisture or other contaminants from entering the jar. This will prolong the shelf life of the product and ensures that it is of the highest quality.

- Improve safety: the liner can be designed with additional safety features such as tamper-evident or child-resistant seals. These features help to ensure that the product is safe and secure.

- Customised performance: Liners can be made from different materials and in such a way to provide specific performance characteristics such as moisture or oxygen barrier properties.

Create your unique closure

Your packaging is the extension of your brand and with it being matching to your brand, you create a lasting impression on your customer.

The options to personalize the closure or cap to your packaging are:

- Embossing & debossing: this technology allows you to add a tactile element to your closures, giving them a three-dimensional effect that is sure to grab the attention. With embossing, the design is raised above the surface of the closure, while the debossing is pressed into the surface. This option is perfect when you want to create an elegant, high-end touch to your packaging.

- Possible from 50.000 pieces

- Print on metal closure: with this option you can choose any design in any colour to match perfectly your brand or to create a unique message.

- Personal colours: you can choose any colour for PP and PE closures to match your brand. This is a great option when you want to create a cohesive look across all of your packaging.

The benefit of your logo being embossed or debossed over printing is that there is only a one-time investment to be done in the mould to add your logo whereas for printing the costs of the print have to be paid with each production run.

Contact Pont Packaging

Quotes, advice, logistics, Orders, Samples

At Pont Packaging, we are committed to help you create packaging that stands out and makes a statement. The personalization options give you the freedom to create a custom look that perfectly represents your brand.